We have recently purchased two Epson SureColor P950 printers, and it’s a mixed bag. We bought them to replace two P-9000’s, and because we needed something faster, we chose the Epson SureColor P9570.

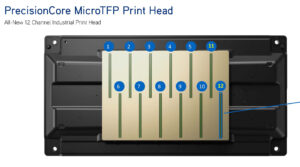

First, the P-9570 is fast. There is no question that having twice the speed helps in a production environment. So that part is good. The Epson P9570 achieves this speed increase because the print head is twice as large is its predecessors.

The color is good, although I’m not sure why Epson changed from Light Black and Light Light black to Grey and Light grey, although it probably has something to do with the light grey containing a chroma optimizer which is used to reduce bronzing, especially in black and white prints. But the gamut of the P9570 is supposedly wider than previous models, and if anything sometimes the color is a little too rich. Ink limiting and good linearization helps with this, and everyone seems to struggle with ink linearization on this model.

Other than the speed, there are a few nice things about it. Users have access to the head area, which is now accessible from the back. The printer parks the head on the left side of the printer, and you can directly access the head for cleaning and maintenance. The capping station is also much more accessible making regular maintenance easier.

The P9570 also has a light in the printer, so it’s easier to see what’s going on while it’s printing. And lastly, you can use photo ink and matte ink without switching inks, and that is a real advantage for those of us that use multiple papers. Anyone familiar with ink switching on the Epson series printers understands that this is a welcome and major feature. Switching from Matte to Photo black almost always triggers a cleaning, which not only costs money, but it takes time and becomes a constant annoyance.

But all that being said, our satisfaction with the Epson SureColor P-9570 is rather low due to issues revolving around paper loading. The entire paper loading process is fraught with issues, and we have had service techs out three times now in the first few months of owning them, only to really find out that the troubles we are seeing are very common.

First, the P9570 cannot take 75 ft rolls of Moab Entrada. The P9570 insists that the cover be closed during printing, and with thicker rolls of paper, the printer stuffs paper into the roll paper cover while loading paper, and it ruins the paper, and will sometimes damage the printer itself, breaking the small white piece that holds the paper core plugs in place and turns them (part #610). And since Epson specifically markets this as a fine art printer, this is an unacceptable shortcoming.

Also, we’ve had issues for years now with Moab Entrada and Canson Aquarelle and Canson Velin coming off the rolls. They always come off the core towards the end, but with the P-9570, they’re coming off the rolls much sooner, and as soon as they do, the printer can’t function. It spits out a good 4-5 feet of paper, and then says “paper not detected”. And at that point you have to remove the paper (usually with several errors on the control panel), tape the paper to the core again, and then put it back. With previous models, like the Epson 9900 and P-9000, with the cover open, it would send some paper up into the core area, but with the cover open it wasn’t an issue. We could continue printing. But with the P-9570, we have had to tape every single roll of paper back onto the core, every single time. It’s tedious and time consuming, and it’s damaging paper, and costing us employee time and aggravation. And we have two of them, so we know it’s not an issue with a particular printer.

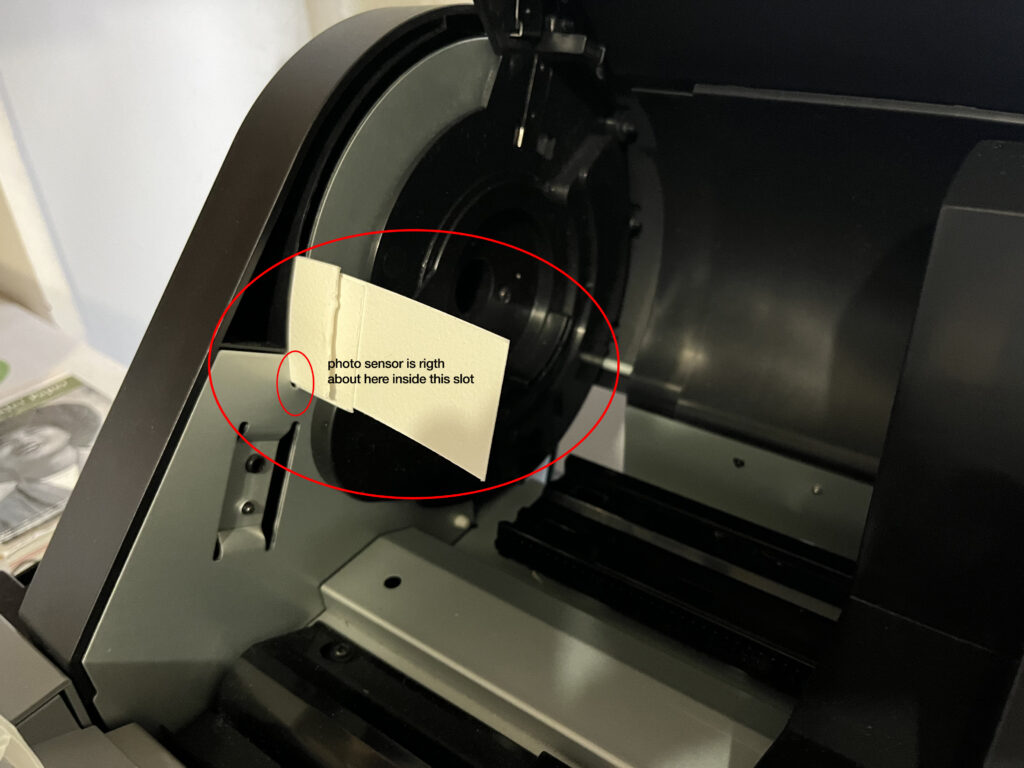

We have found a workaround to some of this, however, and it entails tricking the printer into thinking the cover is closed. To do this, there is a groove on the left side of the printer where the paper roll cover closes, and in that groove is a photo sensor that detects when the roll paper cover is closed. Simply putting a small piece of paper in that slot tricks the printer into thinking that the cover is closed, and eliminates the problem of the printer damaging paper and itself by stuffing paper into that paper cover. That being said, we still have many issues with paper being ripped off the paper core repeatedly, even after retaping, and with it ejecting 4 to 5 feet of paper and giving us an errror.

We have found a workaround to some of this, however, and it entails tricking the printer into thinking the cover is closed. To do this, there is a groove on the left side of the printer where the paper roll cover closes, and in that groove is a photo sensor that detects when the roll paper cover is closed. Simply putting a small piece of paper in that slot tricks the printer into thinking that the cover is closed, and eliminates the problem of the printer damaging paper and itself by stuffing paper into that paper cover. That being said, we still have many issues with paper being ripped off the paper core repeatedly, even after retaping, and with it ejecting 4 to 5 feet of paper and giving us an errror.

[b]LCD menu errors:[/b] I have a theory that Epson had a summer intern program the LCD menu panel. I’ve never seen so many false errors in my life. It will say “close the cover”, and then “paper not detected. Open the cover”, and other such things. All of it’s programming is done around that cover being opened and closed, but it gets confused often, and isn’t sure what it wants. So you have to play a game of open the cover, close the cover, until it figures it out. It’s a complete waste of time.

Another LCD menu issue is that when you’re finished with a roll of paper, and it’s ejected, you close the cover, and the LCD menu says “Set Paper”. When you press that, it forces you into setting paper. But the Home button doesn’t work at that point. There is no way to get out of that menu, so if you want to see the menu, and look at ink levels, etc, then it won’t work. You have to set the paper. I called Epson, and they said that was “normal”. I did, however, discover a workaround, by taking advantage of the fact that the P-9570 gets confused. If you just open and close the cover a few times, it eventually acts like it has rolled paper in it, and you can access the menu. Opening the cover again causes the “set paper” button to reappear. Clearly the menu on the P-9570 needs to be completely revised. It also looks like the most recent firmware may have resolved some of these issues, but the menus on the LCD menu are still quite annoying, and it will ask you to open the roll paper cover when it’s already opened, and give other similar errors on a very regular basis.

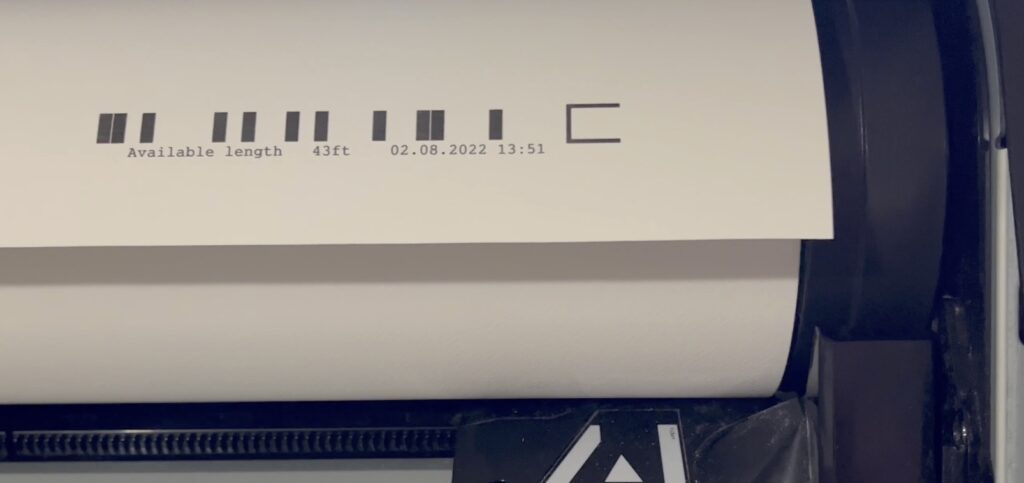

[b] Paper Remaining [/b] The P-9570 has a new function called paper remaining. When you first put on a roll of paper, you can tell it how much is remaining, and it will keep track for you. On the surface, this is a nice functionality. But in reality, it really only works if you never take the paper off the printer.

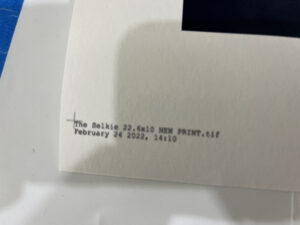

When you remove paper from the Epson P9570 and “paper remaining” is turned on, it will print what looks like a strange bar code kind of thing on the paper, and the idea is that next time you load the paper, the printer will know how much is remaining. But in reality, we have not gotten it to work like that, and there is no documentation on this feature at all. What we have found is that if you reload paper like this, you need to read the code manually, and tell the printer the paper type you’re loading, and manually put in how much paper is remaining in the paper type area. If you don’t, the printer doesn’t recognize that the bar code is there. If you enter a different number, it gives an error. But if you manually read the bar code and enter that value when you reload a paper, then it will continue to keep track of the paper remaining and cut off the bar code before it begins printing. Which brings me to the last comment, which is, why is it necessary to use 2 1/2″ inches of paper to achieve this? It could have been done with less than an inch of paper, and is kind of wasteful.

[b]Epson Driver Issues: [/b] Epson decided to remove a bunch of functionality from the driver, like dry time and paper feed adjustment. Those are very often used functions for adjusting for things like canvas slippage, and for resolving slight banding issues with feed adjustment, but they are gone in the driver. Dry time is also gone, and often we would increase dry time for substrates that don’t dry fast, like removable adhesive vinyl.

This functionality is now part of the Epson Media Installer, which is Epson’s new solution to managing advanced settings like paper feed adjustment and suction. In order to do this, the user needs to create a new paper type, and make those settings in the paper type in the EMI. The paper attributes of the new paper type then get installed to the printer, and under paper types it will be available in the LCD menu.

There is both good and bad about this. On one hand, it’s nice to have customized paper types available on the printer, but on the other hand, it’s impossible to do one off adjustments for a problematic print.

As for us, we use Colorbyte’s Imageprint, and convinced them to use the API to put that functionality back (it was still in their menu but wasn’t working), so we do have a solution with our RIP, but unless your RIP continues to offer this functionality, you won’t find it in the printer drivers or the LCD menu anywhere. Colorbyte Software fixed Imageprint so that feed adjustment does work correctly now in paper options, but the suction still needs to be controlled on the printer’s LCD panel.

[b] Paper Meandering [/b] We have seen paper skew from time to time on previous models, like the Epson P9000 and the 9900, but it was never a huge issue. Now we get the “paper meandering” error ALL the time. We always have to ignore it, because it wants you to unload and reload the paper, but it will continue to meander, as if it has somewhere to go. This error is so common that you need to keep an eye on the printer and make sure it’s still printing, otherwise it will sit and do nothing until you tell it to ignore the issue.

And sometimes when you ignore the issue, it prints blurry as the paper shifts, and then you have expensive misprints. We get misprints like this often – almost every day at some point. Paper meandering, paper skews, and random blurry prints.

[b]Ink Waste [/b] We have opened and checked cartridges that are “empty” and some of them have used most of the ink, but it’s still very common to open an ink cartridge that says it’s empty, and find 100ml or more of ink left in a 700ml cartridge. It’s hit and miss, and there has been no improvement there.

[b] Color [/b] The color is good. It is richer than the P-9000, and sometimes too rich. We’ve managed to make some good profiles and we do get rich color, and in my opinion the color is still better than the Canon printers, especially since Canon elected to remove the green ink in their latest line of printers. In fact, we purchased a Canon Pro 1000 to test the color and profile it, and see if we could consider moving to Canon, but found that the color gamut was lacking compared to the Epson Printers, even the P9000.

[b] Conclusion [/b] For the first time in years, Epson has offered a new aqueous printer that has some new and exciting functionality that should have commercial printers excited, such as no black ink switching, twice the speed, easier cleaning and maintenance, and a wider color gamut. But the execution has been so terrible, that you can’t help but hate the printer half the time. The amount of errors from the printer, misprints, poorly thought out menus, and wasted time and paper are definitely things Epson needs to improve on. Most of this should be solvable in firmware and software, if Epson chooses to address the issues, but as it stands, this is the most problematic implementation of their drivers and printer firmware we have ever seen in our 14 years of business.

Videos: